ELFI MSCR-PP 1 1/2-7 Suction Scanner Self Cleaning Filter 1 1/2" 25 to 300 micron 8-15 m³/hr

ELFI MSCR-PP 1 1/2-7 Suction Scanner Self Cleaning Filter 1 1/2" 25 to 300 micron 8-15 m³/hr

SKU:1666000001

Share

Applications

- Pre-filtration in UF systems

- Pre-filtration for water treatment plants

- Evaporation and cooling towers

- Spray nozzle protection

- Heat exchangers

- Irrigation

- Sea Water

Key Features

- Self-cleaning filters with no interruption to service during cleaning cycle

- Reduction in shutdown time and increased plant availability

- Reduction in maintenance costs

- Highly effective in the removal of suspended solids

- No need for replacement filter cartridges

- Reduced energy consumption

- Reduced consumption of discharge water

- Saves costs on disposable consumables

- Stops filter cartridges going to landfill

HOW IT WORKS

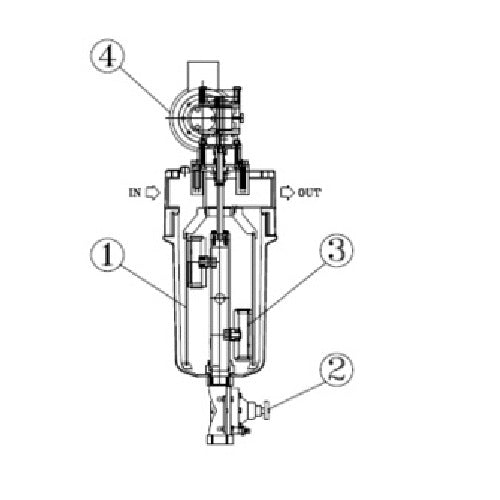

Water enters the filter through the IN inlet and goes through the filtering cylinder from the inside to the outside. This will retain all non-deformable suspended solids that are the same size or bigger than the filtration degree installed. Filtered water leaves through the outlet pipe (OUT).

REGENERATION

The continuous settling of suspended solids inside the filtering cylinder obstructs the passage of water which results in a pressure difference (?P). At a pre-set value of ?P (range 0.3 ÷ 1 Bar) an automatic cycle will start to clean the filter cylinder, this operation begins with a signal that opens the discharge valve (2) and creates communication between the suction nozzles (3) with the outside environment. At the same time, the electric motor (4) creates a rotating motion which enables the nozzles to inspect the filtering surface. Dirt is ejected through the discharge valve (2). The cleaning cycle lasts approximately 15 seconds.

CONTROL

A switchboard controls the washing phases. The signal that starts the cleaning cycle is given by a differential pressure switch. The switchboard gives an “alarm” signal in case of problems in the washing system. These signals can be sent to a pre-existing control centre. The washing phase can also be controlled manually. The solenoid controlling the valve is pneumatic.

ELFI MSCR-PP 1 1/2-7 Suction Scanner Self Cleaning Filter 1 1/2" 25 to 300 micron 8-15 m³/hr

Applications

- Pre-filtration in UF systems

- Pre-filtration for water treatment plants

- Evaporation and cooling towers

- Spray nozzle protection

- Heat exchangers

- Irrigation

- Sea Water

Key Features

- Self-cleaning filters with no interruption to service during cleaning cycle

- Reduction in shutdown time and increased plant availability

- Reduction in maintenance costs

- Highly effective in the removal of suspended solids

- No need for replacement filter cartridges

- Reduced energy consumption

- Reduced consumption of discharge water

- Saves costs on disposable consumables

- Stops filter cartridges going to landfill

HOW IT WORKS

Water enters the filter through the IN inlet and goes through the filtering cylinder from the inside to the outside. This will retain all non-deformable suspended solids that are the same size or bigger than the filtration degree installed. Filtered water leaves through the outlet pipe (OUT).

REGENERATION

The continuous settling of suspended solids inside the filtering cylinder obstructs the passage of water which results in a pressure difference (?P). At a pre-set value of ?P (range 0.3 ÷ 1 Bar) an automatic cycle will start to clean the filter cylinder, this operation begins with a signal that opens the discharge valve (2) and creates communication between the suction nozzles (3) with the outside environment. At the same time, the electric motor (4) creates a rotating motion which enables the nozzles to inspect the filtering surface. Dirt is ejected through the discharge valve (2). The cleaning cycle lasts approximately 15 seconds.

CONTROL

A switchboard controls the washing phases. The signal that starts the cleaning cycle is given by a differential pressure switch. The switchboard gives an “alarm” signal in case of problems in the washing system. These signals can be sent to a pre-existing control centre. The washing phase can also be controlled manually. The solenoid controlling the valve is pneumatic.