ELFI MSCR-PP Micron 1 1/2"-7 Suction Scanner Self Cleaning Filter 1 1/2" 1 to 20 micron 2.5-10 m³/hr(Sintered Fibre 3D)

ELFI MSCR-PP Micron 1 1/2"-7 Suction Scanner Self Cleaning Filter 1 1/2" 1 to 20 micron 2.5-10 m³/hr(Sintered Fibre 3D)

SKU:1666000076-MSCR-PP-112-7-1µ

Share

ELFI MSCR-PP Micron 1½"-7 Self-Cleaning Suction Scanner Filter | 1–20 Micron | 2.5–10 m³/hr (Sintered Fibre 3D)

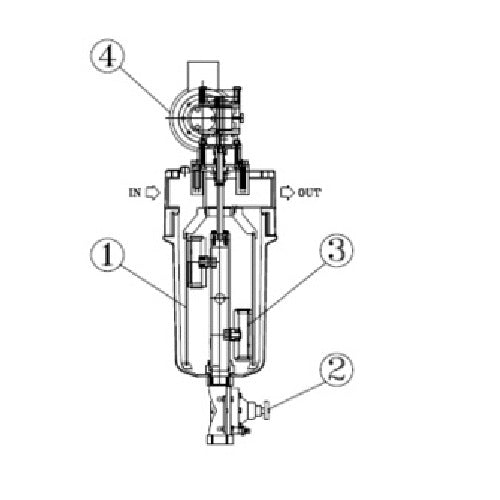

The ELFI MSCR-PP 1½"-7 Suction Scanner Self-Cleaning Filter is an advanced, fully automatic filtration solution engineered for industrial, commercial, and municipal water treatment environments. Featuring Sintered Fibre 3D technology, this system delivers precision filtration from 1 to 20 microns, providing reliable removal of suspended solids while maintaining constant flow — with no downtime and zero consumable filter cartridges.

This model is ideal for high-demand applications needing continuous, maintenance-efficient filtration with reduced operating costs and enhanced system protection.

Key Features

✔ Continuous Self-Cleaning — No System Downtime

- Cleaning cycle activates automatically

- Filtration continues uninterrupted during cleaning

- Eliminates manual cleaning and frequent shutdowns

✔ Zero Cartridge Replacement Costs

- No disposable filter cartridges required

- Saves thousands over the system lifespan

- Environmental benefits — prevents cartridge waste going to landfill

✔ High-Efficiency Sintered Fibre 3D Filtration

- Precision particle removal from 1–20 µm

- Highly effective at capturing non-deformable suspended solids

- Protects sensitive downstream equipment and membranes

✔ Reduced Maintenance & Operating Costs

- Lower energy consumption

- Reduced discharge water

- Less downtime = increased plant availability

How the Filtration Works

Filtration Cycle

-

Water enters the filter via the IN inlet.

-

It passes from inside to outside of the sintered fibre cylinder.

-

Suspended solids equal to or larger than the micron grade are retained.

-

Clean, filtered water exits from the OUT port.

Automatic Regeneration Cycle

When the system detects a pressure drop (ΔP) of 0.3–1 bar, the automatic cleaning cycle begins:

-

Differential pressure switch signals the discharge valve

-

Suction nozzles create communication with the external environment

-

Electric motor rotates the suction scanners across the filter media

-

Collected solids are removed through the discharge port

-

Entire cleaning cycle takes approximately 15 seconds

Filtration continues during regeneration — system flow is never interrupted.

System Control

The integrated switchboard manages all washing phases:

- Initiates cleaning using differential pressure signal

- Provides alarm signalling for any washing-cycle faults

- Allows optional manual control of washing cycles

- Solenoid valve is pneumatically operated

- Interfaces easily with existing plant control systems

Ideal Applications

This model is widely used in:

✔ UF (Ultrafiltration) pre-filtration

✔ Industrial and municipal water treatment plants

✔ Evaporation and cooling tower protection

✔ Spray nozzle protection

✔ Heat exchanger protection

✔ Irrigation systems

✔ Sea water pre-treatment

Performance

- Micron Rating: 1–20 µm

- Flow Rate: 2.5–10 m³/hr

- Connection Size: 1½"

- Filtration Media: Sintered Fibre 3D

- Cleaning Cycle: ~15 seconds

- Operation: Fully automatic or manual

Why Choose ELFI MSCR-PP 1½"-7 from Wrekin Water?

- Industry-leading self-cleaning technology

- No consumables, no downtime

- Long service life with reduced operating costs

- Highly durable and ideal for demanding filtration environments

- Trusted by professionals in water treatment, agriculture, and commercial facilities

Upgrade Your Water Treatment System Today

Choose the ELFI MSCR-PP 1½"-7 for unmatched efficiency, sustainability, and continuous protection for your industrial water processes.

ELFI MSCR-PP Micron 1 1/2"-7 Suction Scanner Self Cleaning Filter 1 1/2" 1 to 20 micron 2.5-10 m³/hr(Sintered Fibre 3D)

ELFI MSCR-PP Micron 1½"-7 Self-Cleaning Suction Scanner Filter | 1–20 Micron | 2.5–10 m³/hr (Sintered Fibre 3D)

The ELFI MSCR-PP 1½"-7 Suction Scanner Self-Cleaning Filter is an advanced, fully automatic filtration solution engineered for industrial, commercial, and municipal water treatment environments. Featuring Sintered Fibre 3D technology, this system delivers precision filtration from 1 to 20 microns, providing reliable removal of suspended solids while maintaining constant flow — with no downtime and zero consumable filter cartridges.

This model is ideal for high-demand applications needing continuous, maintenance-efficient filtration with reduced operating costs and enhanced system protection.

Key Features

✔ Continuous Self-Cleaning — No System Downtime

- Cleaning cycle activates automatically

- Filtration continues uninterrupted during cleaning

- Eliminates manual cleaning and frequent shutdowns

✔ Zero Cartridge Replacement Costs

- No disposable filter cartridges required

- Saves thousands over the system lifespan

- Environmental benefits — prevents cartridge waste going to landfill

✔ High-Efficiency Sintered Fibre 3D Filtration

- Precision particle removal from 1–20 µm

- Highly effective at capturing non-deformable suspended solids

- Protects sensitive downstream equipment and membranes

✔ Reduced Maintenance & Operating Costs

- Lower energy consumption

- Reduced discharge water

- Less downtime = increased plant availability

How the Filtration Works

Filtration Cycle

-

Water enters the filter via the IN inlet.

-

It passes from inside to outside of the sintered fibre cylinder.

-

Suspended solids equal to or larger than the micron grade are retained.

-

Clean, filtered water exits from the OUT port.

Automatic Regeneration Cycle

When the system detects a pressure drop (ΔP) of 0.3–1 bar, the automatic cleaning cycle begins:

-

Differential pressure switch signals the discharge valve

-

Suction nozzles create communication with the external environment

-

Electric motor rotates the suction scanners across the filter media

-

Collected solids are removed through the discharge port

-

Entire cleaning cycle takes approximately 15 seconds

Filtration continues during regeneration — system flow is never interrupted.

System Control

The integrated switchboard manages all washing phases:

- Initiates cleaning using differential pressure signal

- Provides alarm signalling for any washing-cycle faults

- Allows optional manual control of washing cycles

- Solenoid valve is pneumatically operated

- Interfaces easily with existing plant control systems

Ideal Applications

This model is widely used in:

✔ UF (Ultrafiltration) pre-filtration

✔ Industrial and municipal water treatment plants

✔ Evaporation and cooling tower protection

✔ Spray nozzle protection

✔ Heat exchanger protection

✔ Irrigation systems

✔ Sea water pre-treatment

Performance

- Micron Rating: 1–20 µm

- Flow Rate: 2.5–10 m³/hr

- Connection Size: 1½"

- Filtration Media: Sintered Fibre 3D

- Cleaning Cycle: ~15 seconds

- Operation: Fully automatic or manual

Why Choose ELFI MSCR-PP 1½"-7 from Wrekin Water?

- Industry-leading self-cleaning technology

- No consumables, no downtime

- Long service life with reduced operating costs

- Highly durable and ideal for demanding filtration environments

- Trusted by professionals in water treatment, agriculture, and commercial facilities

Upgrade Your Water Treatment System Today

Choose the ELFI MSCR-PP 1½"-7 for unmatched efficiency, sustainability, and continuous protection for your industrial water processes.